Products

Detailed

DESCRIPTION

The vertical woltmann water meter is a velocity water meter, and its impeller rotation direction is perpendicular to the direction of water flow. When water flows through the water meter, it drives the spiral rotor to rotate, and its speed is proportional to the water flow rate. The sensors inside the water meter can measure the rotational speed of the helical rotor, thereby calculating the water flow rate.

FEATURE

● Dry type structure:The counting mechanism is vacuum sealed, the dial and numerals aren’t impacted by the water quality,and the readings can be clear permanently.

● High accuracy: Some large diameter mechanical water meters have higher measurement accuracy,such as low starting flow 、 wide measurement range 、 high measurement accuracy,can measure the total volume of water flowing through pipelines accurately.

● Stable performance:Fewer mechanical parts,low failure rate ,relatively stable performance, can work stably in the various environments for a long time.

● Widely application conditions:Suitable for agricultural irrigation, main pipelines, firefighting pipelines, factories, etc., able to meet the water consumption characteristics and measurement needs of users in different industries.

● High pressure resistance:able to withstand higher working pressure and meet the requirements of high-pressure water supply systems.

● Simple structure:Compared to some smart water meters,the mechanical water meters have a simpler structure and are relatively easier to maintain.

● Easy to replace:High degree of standardization of parts ,when a component is damaged,it is convenient to replace.

WORKING CONDITION

Model:WS-40~200

Material: Iron

Accuracy: Class B

Temperature: T30/T90

Pressure class:MPA10

Pressure loss class:△p63

Installation: Horizontal

MAIN TECHNICAL DATA

|

Size DN |

Q3/Q1 |

Overload Flow Q₄ |

Nominal Flow Q3 |

Transitional Flow Q₂ |

Minimum Flow Q1 |

Min Reading |

Max Reading |

|

m³/h |

L/h |

m³ |

|||||

|

40 |

160 |

31.25 |

25 |

250.0 |

156.3 |

0.00005/0.0005 dry type 0.00025 |

999999 |

|

100 |

400.0 |

250.0 |

|||||

|

50 |

200 |

50 |

40 |

320.0 |

200.0 |

0.0005 dry type 0.00025 |

|

|

160 |

400.0 |

250.0 |

|||||

|

80 |

200 |

78.75 |

63 |

504.0 |

315.0 |

0.0005 dry type 0.001 |

|

|

160 |

630.0 |

393.8 |

|||||

|

100 |

200 |

125 |

100 |

800.0 |

500.0 |

||

|

160 |

1000.0 |

625.0 |

|||||

|

150 |

250 |

312.5 |

250 |

1600.0 |

1000.0 |

0.005 Dry type 0.0025 |

9999999 |

|

200 |

2000.0 |

1250.0 |

|||||

|

160 |

2500.0 |

1562.5 |

|||||

|

200 |

250 |

500 |

400 |

2560.0 |

1600.0 |

||

|

200 |

3200.0 |

2000.0 |

|||||

|

160 |

4000.0 |

2500.0 |

|||||

|

|

|||||||

|

The maximum allowable error for the low region (Q1≤Q<Q2) is ±5%; The maximum allowable error for the high region (Q2≤Q≤Q4) is ±2%. |

|||||||

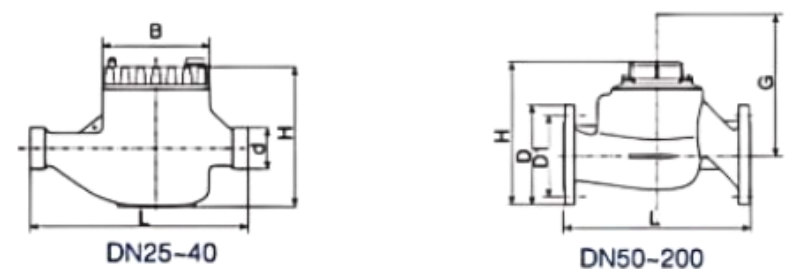

DIMENSIONS AND WEIGHT

|

Size DN |

Length L |

Height H |

Height G |

Connecting Thread |

Weight |

|||

|

mm |

d |

D |

Kg |

|||||

|

40 |

245/280 |

154/184 |

180/260 |

R1 1/2 |

G 2B |

6/12 |

||

|

Size DN |

Length L |

Height H |

Height G |

Connect Flange |

Weight |

|||

|

Flange diameter D |

Bolt Hole Center Diameter D1 |

Bolts Quantity |

||||||

|

mm |

P |

Kg |

||||||

|

50 |

280 |

260 |

300 |

165 |

125 |

4×M16 |

17.5 |

|

|

80 |

370/225 |

285/270 |

300 |

200 |

160 |

8×M16 |

22/18 |

|

|

100 |

370/250 |

310 |

345 |

220 |

180 |

8×M16 |

27/23 |

|

|

150 |

500 |

375 |

445 |

285 |

240 |

8×M20 |

51 |

|

|

200 |

500 |

455 |

605 |

340 |

295 |

8×M20 |

80 |

|

|

|

||||||||

|

The appearance dimensions and weight are for reference only, subject to the actual product or customized according to customer requirements. |

||||||||

Recommended Products

Online Message